Let us help you with Ship Emissions & Fuel Sulfur Content Monitoring!

How Can Scentroid's help with

Monitoring Ship Emissions & Fuel Sulfur Content

Navigating our DR2000 Advanced Flying Laboratory into ship/naval vessel plumes, pilots can now analyze the gas composition to determine the Ship Emissions & Fuel Sulfur Content (FSC). As a result of monitoring FSC emissions caused by ships, mitigation solutions can be investigated, allowing for a reduction in air pollution for coastal port cities due to ship exhaust.

When equipped with the appropriate sensor load-out, the DR2000 can fly near downwind exhaust plumes and quickly determine pollutant levels. A real-time algorithm calculates the sulfur to carbon ratio and the sulfur content of the ship’s fuel. The DR2000 can monitor a vessel without boarding it. In just a few minutes, we can determine the average fuel consumption content (FSC).

Drone-Based Analyzers

Scentroid’s Drone Based Air Quality Monitors continue to improve upon the collection and monitoring of airborne chemicals. It can go where no ambient air monitor has gone before; virtually everywhere!

Pollutants from Naval Vessels / Ships

The following is a list of recommended monitoring options for your industry:

- Carbon Dioxide (CO2)

- Methane (CH4)

- Nitrous Oxide (N2O)

- Sulphur Oxide (SOx)

- Volatile Organic Carbons (VOC)

- Particulate Matter (PM1, 2.5, 10)

- Nitrogen Oxides (NOx)

- Plus More

How It Works

Initial Analysis

Determine ambient air levels without direct emissions testing. This is done to obtain background concentration values of monitored gasses

Exhaust Testing

The DR2000 then analyses the exhaust plume, maintaining a fixed distance/altitude. This is completed several times to ensure optimal readings

Real-time Reporting

Ground Station software further calculates and displays a Sulfur Content Reading of the naval vessel in real-time

Post Analysis

The pilot will have now have access to aerial photos, thermal imaging (if applicable), reports, and all monitoring related data

DRIMS2

Drone Information Management System

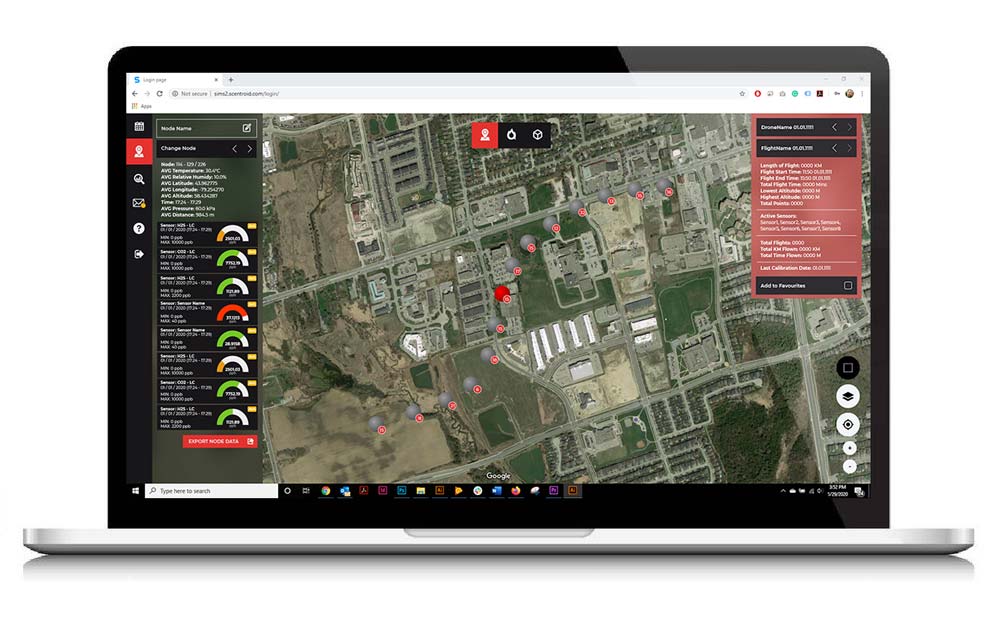

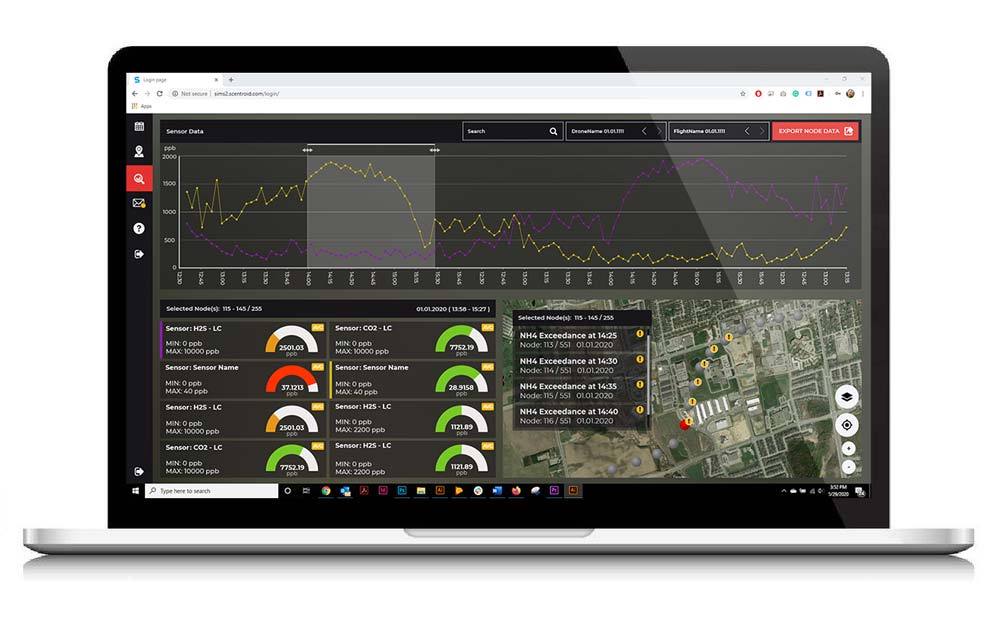

The Scentroid Drone Information Management System, DRIMS2, our all-inclusive software, is used to view historical data, run diagnostics, configure, and set alarm levels for DR2000. Provided as part of the DR2000 package, the software is installed on our on-board server (default), Scentroid’s cloud-based server (default) and on your localized server (optional).

DRIMS2 is easy to use graphical interface allows anyone to run complicated data analytics without being a GIS expert. It can control and display data from multiple DR2000s in the same fleet. Users can analyze data and monitor progress remotely from a single platform.

DRIMS2 All-Inclusive Software

DRIMS2 provides easy analysis tools for an operator to determine pollutant hot spots, possible sources, sampled areas, and much more.

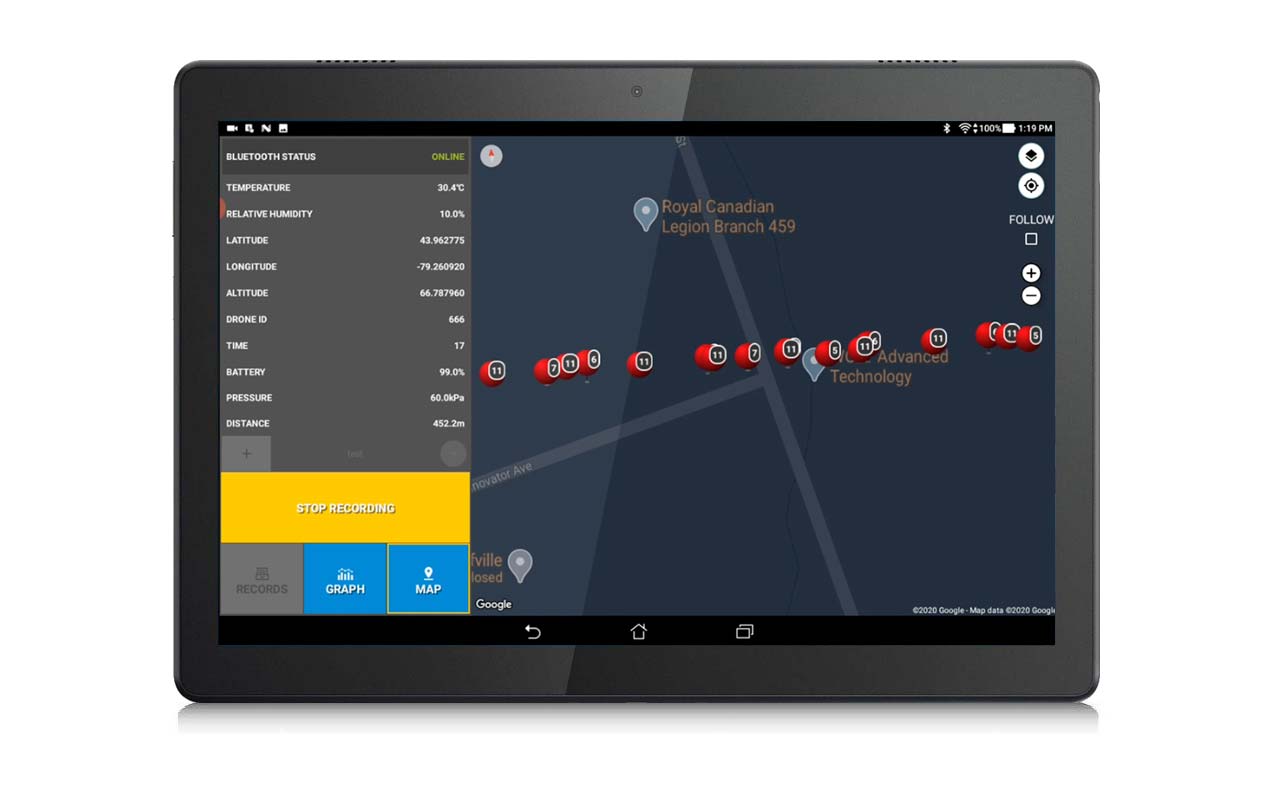

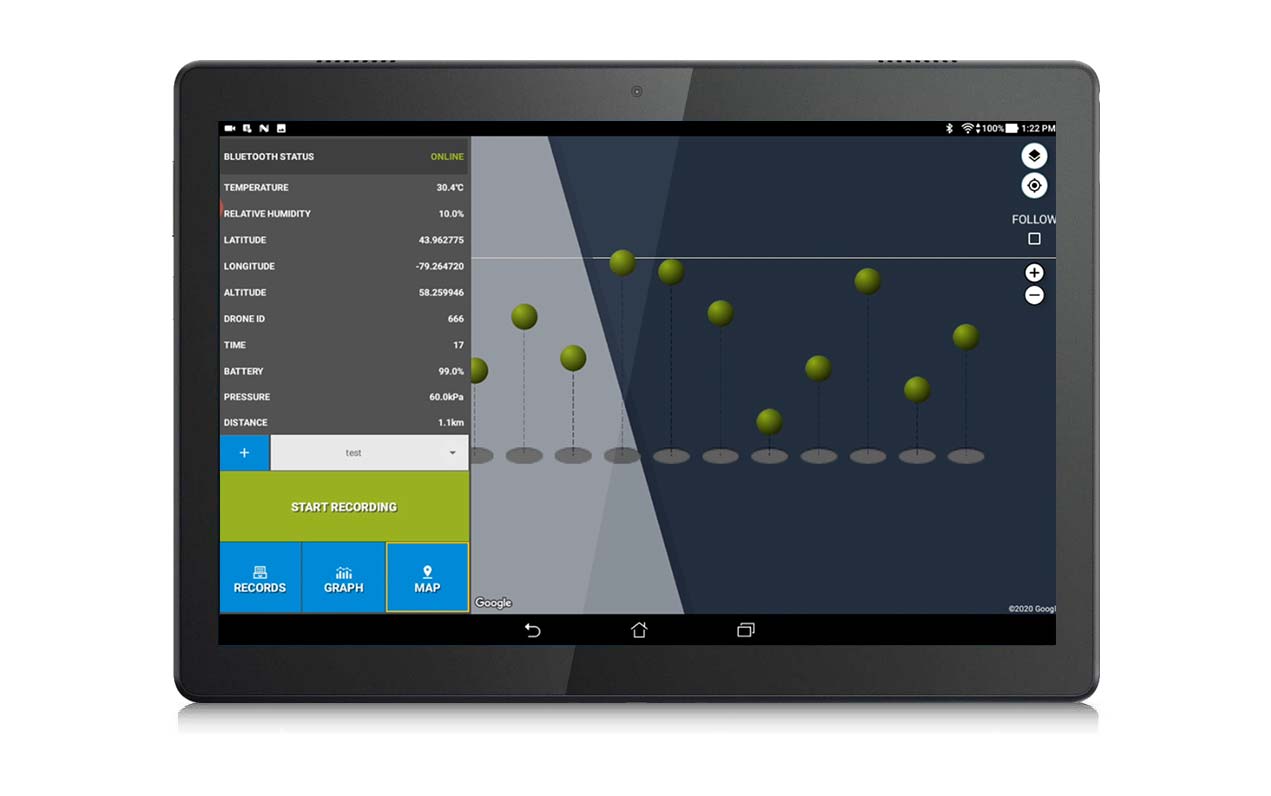

Ground Station

The Scentroid ground station consists of a specialized tablet connected to a miniature PC with a high-gain, powerful communication antenna. Our tablets come pre-installed with our DRIMS2 Ground Station component software. This branch of DRIMS2 software allows users to log all acquired data as it occurs, including live and historical data for sensors such as GPS position, altitude, temperature, and humidity.

Users can also command the drone to take samples and perform routine maintenance, such as calibrating sensors. The readings are continuous, and users can choose to display them live with our diagnostics feature or forward them to a database. If an optional on-board camera is present, the ground station will receive a video feed for simultaneous viewing.

Analysis Software

The DR2000 comes with simultaneous GPRS and Wi-Fi communication capabilities. The GPRS is used to send data to our Scentroid cloud server. Besides using the Ground Station to communicate with our DRIMS2 system, you can also log into our secured DRIMS2 portal using any PC / laptop with a stable internet connection.

Our DRIMS2 Analysis software serves as the perfect companion to any monitoring job – an offsite wealth of information is stored in a beautiful and easy to navigate interface. After securely logging in, users can select their drone, select their flight date, favorite, name, or even search for a specific sampling node.

With access to a heat map along with viewing altitude in a 3D setting, managing a sensory project has never been easier (or more informative!).

Recommended

Scentroid Services

Scentroid provides a comprehensive site overview. Our team of qualified engineers and technicians will formulate a sampling plan and take analytical and olfactometric measurements and samples at key locations. Scentroid analyzes samples on-site using portable analyzers and olfactometers before shipping them to a comprehensive analytical (ISO 17025) and stationary olfactometric laboratory (EN13725). After we analyze the samples, we process the data and compare it against pertinent regulations, guidelines, and standards. If we find an exceedance of pollutants, Scentroid will recommend suitable approaches to ensure environmental compliance.

Determine the severity and extent of the pollutant/odour emissions from your facility. Simulations are processed using the US-EPA designed and approved, AERMOD modelling suite.

Send us your sample bags and our Olfactometric Laboratory will determine their odor concentration in accordance to EN13725:2022, ASTM E679-04, NVN2820, VDI 3881, GB/T14675-93 and/or AS 4323.3.

Other Scentroid Services

Seek advice from our odour monitor experts and environmental consultants to help you improve the accuracy and reliability of your monitoring projects.

Air quality mapping, model verification, and analysis of potentially dangerous sites have all now been made possible. While in flight, built-in chemical sensors can provide remote monitoring.

Scentroid offers a complete and integrated suite for ambient air chemical analysis and odor management, known as SIMS3. Our software utilizes a unique and highly intuitive facility control system, and powerful artificial intelligence to assist you with daily tasks.

We can assist with continuously monitoring the air quality around the boundary of your ship. This is typically used in settings where emissions and pollutants may potentially affect a community.

A team that’s equipped with an SM100i Olfactometer, an OdoTracker personal ambient air monitoring device, a thermal camera, and a noise monitor patrols and collects facility data.

Scentroid is capable of providing you and your ships with several reports ranging from SIMS3 outputs, to odour testing results based on your requirements. Several report types can be autogenerated using our SIMS3 platform.

Let us help you with Ship Emissions & Fuel Sulfur Content Monitoring!

Monitoring Devices

Scentroid provides a wide variety of monitoring devices to assist you with managing air quality concerns for your naval vessels / Ships. From drone-based analyzers to handheld analyzers, Scentroid has you covered!

PMD100

PMD100 helps workers in hazardous environments.

Naval Vessels / Ships References

Ontario, Canada

Oman

Vancouver, Canada

Dubai

Saudi Arabia

Chicago, USA