Scentroid's Approach for

Monitoring Air Quality in Pulp & Paper

The process of creating pulp and paper can lead to heavy pollution through both air and wastewater. These processes may not even be confined to the same location. Pulping, bleaching, wastewater management, solid waste creation, and sulfite mills for wood chip digestion are a few of the factors involved.

The combination of stationary equipment, and Odour Patrol device monitoring provides a comprehensive approach to air quality monitoring in Pulp & Paper Production.

Stationary Equipment provide continuous monitoring of indoor and outdoor air quality in and around your facility, providing valuable data on the overall level and distribution of pollution.

Odour Patrol offers an additional layer of monitoring, enabling the detection of hot-spots and a large area in an effective way, along with providing more granular data on the spatial and temporal patterns of air pollution.

Stationary Equipment

Scentroid’s CTmini and CTair continuous monitoring of air quality in and around your facility, providing valuable data on the overall level and distribution of pollution.

Complete Emission Inventory Service

Fugitive Emission Measurement

Emissions of gases or vapors from pressurized equipment due to leaks and other unintended or irregular releases of gases, mostly from industrial activities

Flare or Plume Testing

Safely determining the impact of chemical burn off in active flares or stacks

Complete Emission Inventory

A database that lists, by source, the amount of air pollutants discharged into the atmosphere during a specific time period

Filtration Efficiency

A complete check of all filtration systems and measuring their overall efficiency, ensuring no fugitive emissions

Pollutants from Pulp & Paper

The following is a list of recommended monitoring options for your facility:

- Chlorine Dioxide (CIO2)

- Chlorine (CI2)

- Bisulfite (NaHSO3)

- Volatile Organic Carbons (VOC)

- Particulate Matter (PM1, 2.5, 10)

- Chloroform (CHCl3)

- Acetone ((CH3)2CO)

- Carbon Disulfide Methanol

- Partitioning of Chlorinated Organics

- Pathogens

- Sulfur Oxides (SO2)

- Odorous Compounds

- Nitrogen Oxides (NO)

- Ketones (CnH2nO)

- Plus more

Ask a Scentroid Representative how we can help you with Pulp & Paper Air Monitoring!

Odour Patrol

Scentroid developed the Odour Patrol methodology in 2015 to map the odour impact of the entirety of the city of Ras Laffan in Qatar, and has since been used in Canada, UAE, USA, Italy, Chile and many more countries with great success. This combines the use of the field olfactometer SM100i, and handheld or mobile ambient air quality monitors. These could range from the Scentroid US20, to the DR2000 flying laboratory, and the TR8 Odotracker product lines.

Monitoring Overview

Track your sensitive receptors, and view the direct effects an emission source may have on them, down to the odour unit per second value!

Using “Event Triangulation” SIMS3 can pinpoint the location of unknown sources and determine their contribution to the complaints received

A typical pulp & paper production requires approximately 4-6 air quality monitoring devices strategically stationed around the facility perimeter based on collected data.

Track the impact of upset conditions, odour filter maintenance, sludge deliveries and other facility events using our SIMS3 AI algorithm

Several facility processes may be directly contributing to errant odours. SIMS3 can track the emission rate of all odour sources using amient monitors and reverse dispersion modeling.

Once odour complaints are filed, SIMS3 will collect them and visually present them in a visual, mappable format. SIMS3 will also analyze the contributor of the source that led to the complaint.

Sensitive Receptor: Shopping Mall

Sensitive Receptor: Museum

Sensitive Receptor: Local Restaurant

Sensitive Receptor: Local School

Unknown Odour Source: Recycling Center

Odour Complaints: Nearby Residential Plaza

Factory Event: Digestion

Factory Event: Bleaching

Known Odour Source: Drying

Monitoring Device: Scentroid CTmini or CTair

Monitoring Device: Scentroid CTmini or CTair

Monitoring Device: Scentroid CTmini or CTair

Monitoring Device: UrbanScanner US20

How Can Scentroid Help with

Pulp & Paper Air Quality and Odour Complaints?

Once you activate Scentroid’s devices and enter our software SIMS3, we can use the collected data to determine whether an odour complaint is justified or not. We identify where the great odour sources come from and make justification for you. We also continuously monitoring to help facility maintain better air quality to avoid receiving complaints.

Odour Complaint Justification

Once Scentroid devices are all set and receive all data, SIMS3 will determine whether an odour complaint is justified or not. Red indicates that the complaint was automatically categorized as “justified”, those in green would be recorded, but categorized as “not justified,” those in yellow would be recorded and categorized as “to be justified”. Furthermore, the user can use triangulation to determine the source of unjustified odours.

Triangulation of Unknown Sources

If you are trying to determine the location of potentially unknown sources, SIMS3 offers a triangulation mode and identifier to assist you with pinpointing unknown sources. SIMS3 features the ability to perform triangulation from odour events or from ambient air monitoring equipment readings.

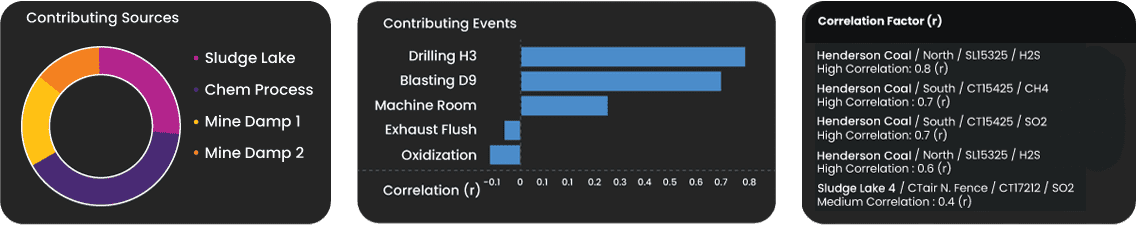

Odour Complaint Analysis

SIMS3 features a correlation module that determines what events caused the greatest odours and what the contributing sources may have been. Furthermore, should your facility’s process events be recorded, SIMS3 will associate those events with odour increases.

Ask a Scentroid Representative how we can help you with Pulp & Paper Air Monitoring!

SIMS3

Sensor Information Management System

SIMS3 sensor information management software, is our all-inclusive software used to view and analyze historical data, run diagnostics, make predictions, and configure various settings for your supported Scentroid device. It offers a complete and integrated suite for ambient air chemical analysis and odor management. SIMS3 can collect data from thousands of devices covering an entire area, using a unique and highly intuitive facility control system.

Powered by

Artificial Intelligence

SIMS3 transforms air quality monitoring and odor complaint management with the power of AI. Our user-friendly interface offers intuitive access to a range of features including pollutant threat assessment, air quality alerts, historical data analysis, sample tracking, plume detection, and complaint management, empowering users of all levels to conduct sophisticated data analytics effortlessly.

Mathematical simulation of how air pollutants disperse in the ambient atmosphere. It is performed with a computer simulation of a pollutant dispersion model

SIMS3 Analytics

View data in several formats including temporal view, statistical view, AQI Analysis view, and heat map.

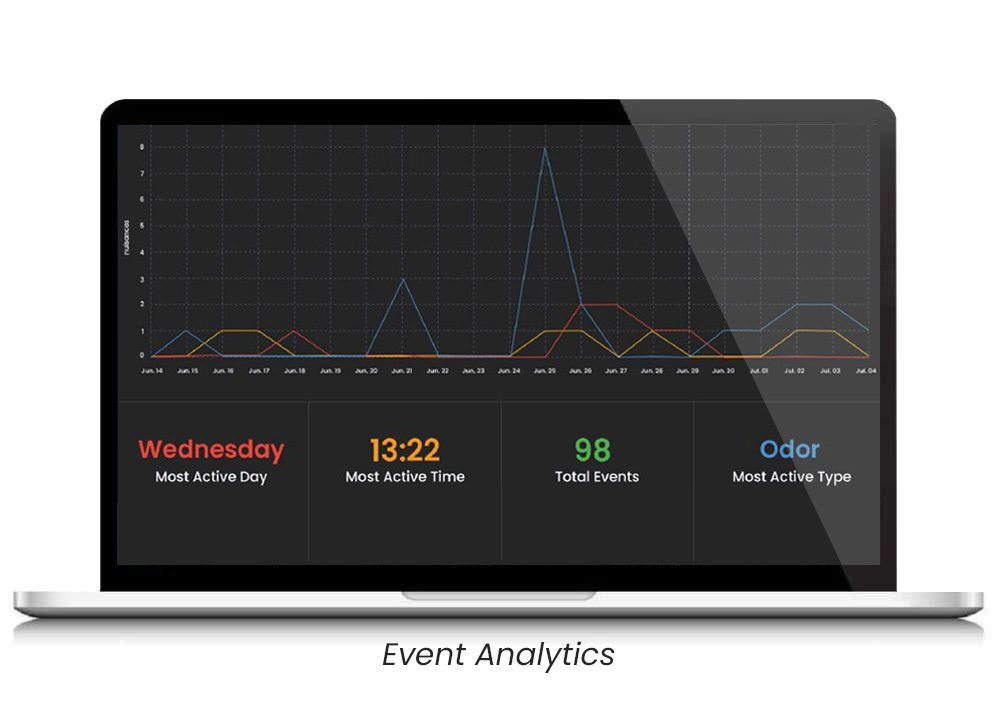

Event Analytics

Take your analytic capabilities even further by analyzing your recorded events, event types, and overall event activity. In this module, you will be able to determine your most triggered event type and the days with the highest recorded activity.

Odor Complaint Analytics

This module allows you to easily determine the justification analytics of all recorded odor events. View which days have had the highest justified or not justified events, view the correlation matrix with contributing events, and see which processes may have a connection to all recorded odor complaints.

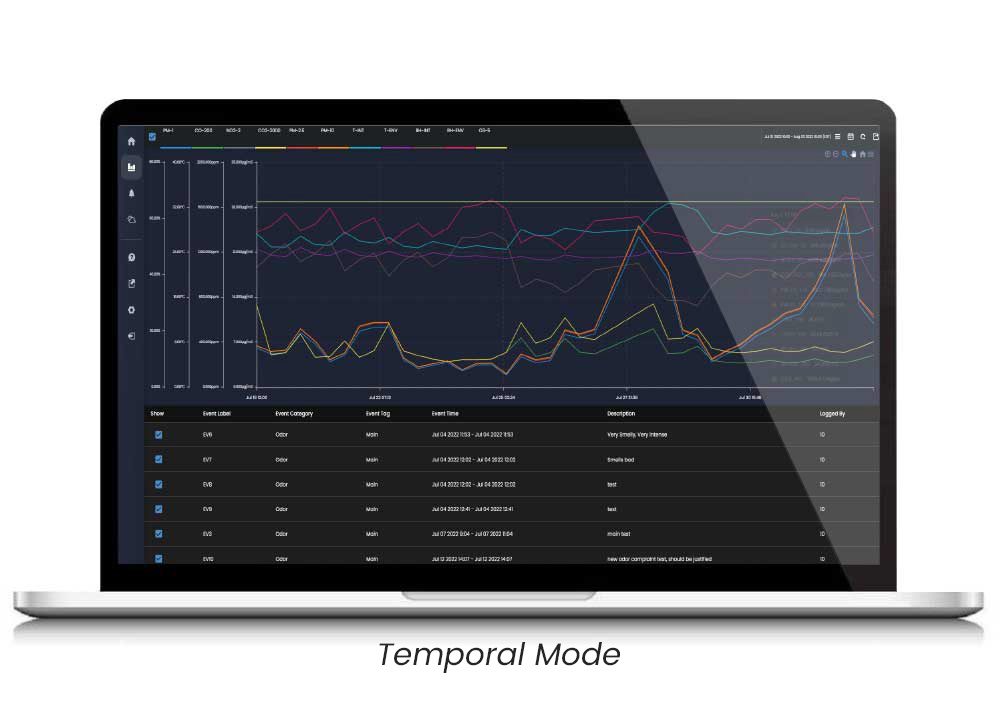

Temporal Mode

As shown here in temporal view, the user can Isolate or compare collected sensor data for any user-defined timeframe in an easy to read chart. Any event or event type that occured within the specified timeframe is also tracked.

Statistical Mode

Isolate and determine individual sensor reading trends with our detailed statistical analysis view. Data is presented as percentages vs concentration for quick reference. A data trend guide displays whether your tracked chemical readings are displaying an increase or decrease.

AQI Analysis

Based on established AQI Thresholds (either automatically generated or user-defined), view recorded AQI for any period of time. This module will also allow you to view how many times AQI exceeded these thresholds, and for how long (percentage).

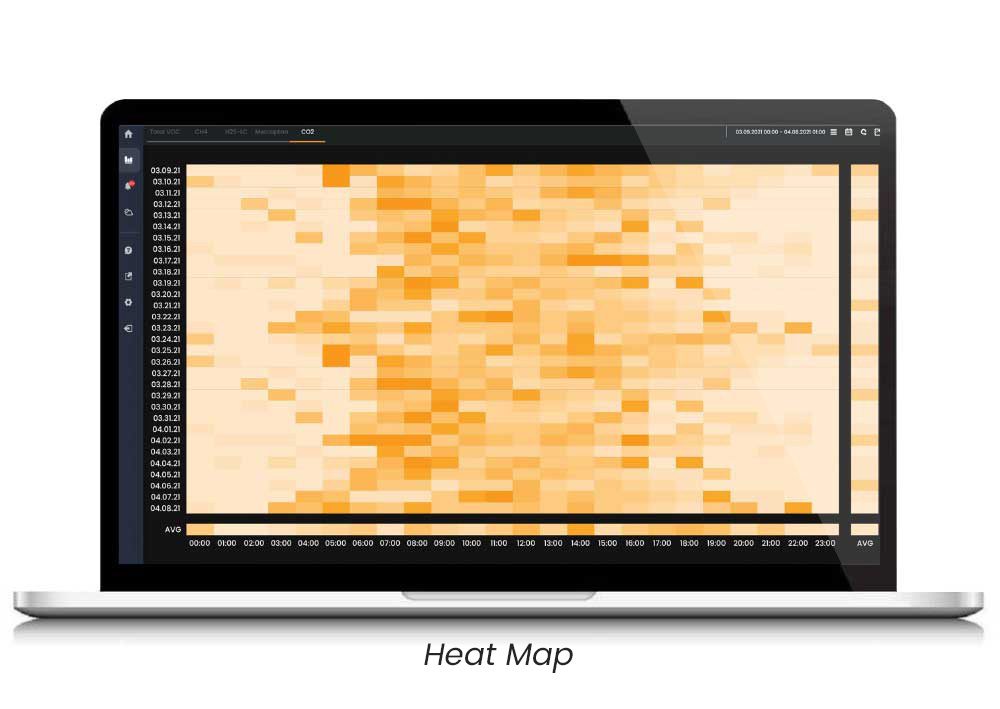

Heat Map

View each individual sensor’s heat map within a user-defined period. Concentration is presented in this format to assist the user with visually defining patterns and trends. Heat map data is presented as date vs. time.

Export Reports

The SIMS3 reporting module provides you with the tools you need to make informed decisions regarding your monitoring projects. At the click of a button, this document generates averages as well as thorough individual sensor reports. Users can schedule weekly, monthly, or annual reports emailed directly to them once generated!

Recommended

Scentroid Services

Scentroid provides a comprehensive site overview. Our team of qualified engineers and technicians will formulate a sampling plan and take analytical and olfactometric measurements and samples at key locations. Scentroid analyzes samples on-site using portable analyzers and olfactometers before we ship them to a comprehensive analytical (ISO 17025) and stationary olfactometric laboratory (EN13725). After we analyze the samples, we process the data and compare it against pertinent regulations, guidelines, and standards. If we find an exceedance of pollutants, Scentroid will recommend suitable approaches to ensure environmental compliance. Additionally, we can include atmospheric dispersion modeling in the environmental impact assessment.

In a processing plant, air contamination should be addressed in 2 separate ways: indoors and outdoors. Most common outdoor contaminants come from waste handling, fugitive emissions, and other related activities. While stack sources remain easy to identify, processing plants have many fugitive sources that greatly contribute to the total odour emission of the plant. Scentroid provides a comprehensive source detection and monitoring as part of its odour and indoor/outdoor air pollution management

Determine the severity and extent of the pollutant / odour emissions from your facility. Simulations are processed using the US-EPA designed and approved, AERMOD modelling suite.

Send us your sample bags and our Olfactometric Laboratory will determine their odour concentration in accordance to EN13725:2022, ASTM E679-04, NVN2820, VDI 3881, GB/T14675-93 and/or AS 4323.3.

Other Scentroid Services

Seek advice from our odour monitor experts and environmental consultants to help you improve the accuracy and reliability of your monitoring projects.

Air quality mapping, model verification, and analysis of potentially dangerous sites have all now been made possible. While in flight, built-in chemical sensors can provide remote monitoring.

Ground level readings are used by SIMS3 to conduct back-trajectory to identify unknown sources. Continuous pollution data and field olfactometric data are used along with meteorological data to triangulate the exact location of an odour source.

Scentroid offers a complete and integrated suite for ambient air chemical analysis and odor management, known as SIMS3. Our software utilizes a unique and highly intuitive facility control system, and powerful artificial intelligence to assist you with daily tasks.

We can assist with continuously monitoring the air quality around the boundary of your facility. This is typically used in settings where emissions and pollutants may potentially affect a community.

A team that’s equipped with an SM100i Olfactometer, an OdoTracker personal ambient air monitoring device, a thermal camera, and a noise monitor patrols and collects facility data.

SIMS3 provides the user with the ability to collect, store, determine the correlation factor, and the justification of all complaints that may have been entered against your facility.

Scentroid is capable of providing you and your facility with several reports ranging from SIMS3 outputs, to odour testing results based on your facility’s requirements. Several report types can be autogenerated using our SIMS3 platform.

Ask a Scentroid Representative how we can help you with Pulp & Paper Air Monitoring!

Monitoring Devices

Scentroid provides a wide variety of monitoring devices to assist you with managing air quality concerns for your pulp & paper facility. From stationary monitors to handheld olfactometers, Scentroid has you covered!

Pulp & Paper References

Ontario, Canada

Oman

Vancouver, Canada

Dubai

Saudi Arabia

Chicago, USA