TOMS

Our TOMS Total Odour Management Software offers a complete and integrated suite for odour management. The system blends real-time odour impact estimation with the registration and management of odour complaints from neighboring residents.

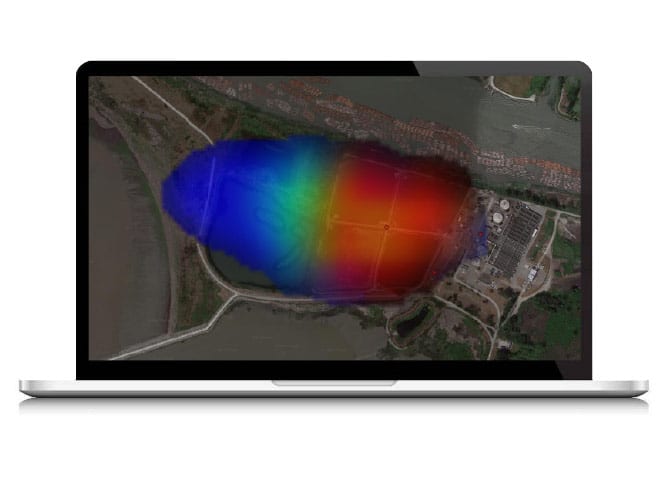

Our easy-to-use software utilizes both continuous pollution monitoring data and live weather data to calculate a real-time odour plume model, displaying the exact location and spread of your odour emissions. Furthermore, the system automatically logs complaints and compares them to odour emissions for quick and efficient validation.

Our TOMS program outlined here follows a simple 4-step methodology to help you tackle any odour situation with ease and certainty.

From estimation to monitoring and odour dispersion, TOMS provides a complete solution for understanding a facility’s total odour impact.

Estimate of Emissions

The first step to fully understanding and solving any odour issue starts with creating an initial estimate of its emissions. This process can be as comprehensive as conducting a full odour inventory. For example, using field olfactometry devices like the SM100i, or as simple as utilizing Scentroid’s extensive emission factor database. Scentroid’s environmental engineers will guide you through this step to ensure you achieve a cost-effective yet accurate initial estimate.

When you address the potential subjectivity of registering an odour complaint, applying a system like this removes a significant source of potential error.

Project Levels of Pollution

The initial odour inventory helps create an odour plume. It indicates how odours will travel and affect nearby residents visually. To calculate this plume, we use USEPA air dispersion modeling software (AERMOD).

The dispersion model considers the odour emissions from each source. While also taking into account local meteorological data, such as wind speed and wind direction. This approach allows us to apply a model to both surface and elevated sources, accounting for both simple and complex terrain variations.

Monitor Pollution Using Total Odour Management Software

Odour emissions constantly change based on processes, ambient weather conditions, or upset situations. TOMS automatically calculates and updates to reflect these changes through live ambient odour monitoring.

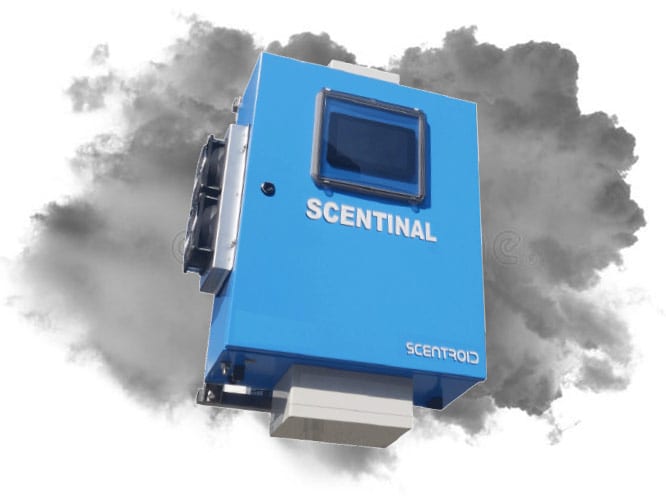

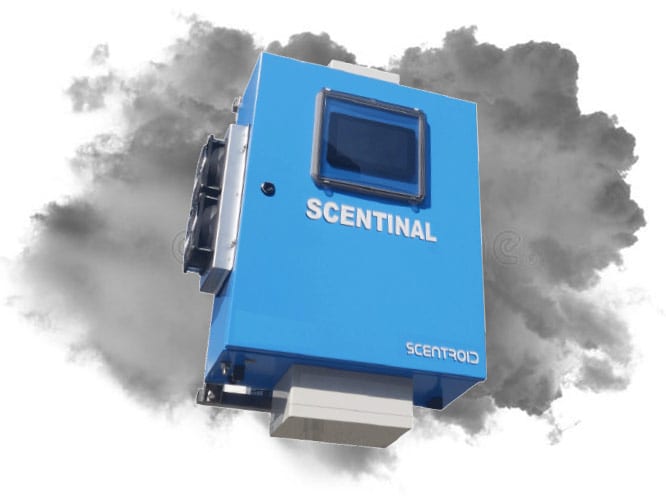

We use monitoring stations, such as the CTair and Scentinal, to measure ground-level odours at facility boundaries, directly over large sources, or at sensitive receptors. Scentroid’s monitoring equipment is specifically designed to detect trace levels (parts per billion) of odorous compounds such as H₂S, NH₃, and VOCs. The system converts the pollutant measurements to odour units (OU/m³) using Scentroid’s deep learning algorithm. Then, we use the collected data in the next phase to compute changes to the source emission rates.

Calculate Error Estimate

The most critical step of TOMS live monitoring is updating the emission estimate based on real ground-level odour measurements. Every minute, TOMS compares its estimated odour level from dispersion modeling to the actual measurements collected through continuous odour monitoring equipment. If a significant difference exists, TOMS adjusts its emission rates to compensate.

The system updates the emission rates using a fuzzy logic algorithm that considers weather data, source variation patterns, detected pollutants, and historical estimates. Users receive an extremely accurate odour emission projection. Users can use the updated emission rates to analyze how sources emit odours over time, which operations are more detrimental to an overall odour control strategy.

TOMS Features

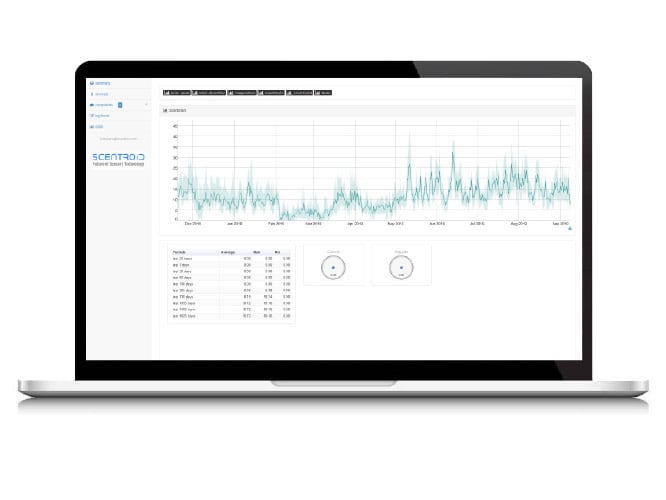

Real-Time Odour Emission Monitoring

This summary page displays a real-time plume and includes a menu for changing users or logging out, adjusting settings, viewing plots based on time and date, displaying open complaints, and accessing weather data for the plot.

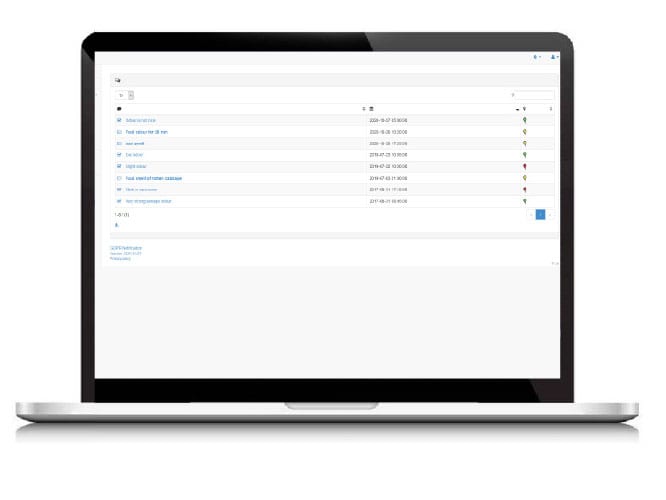

Complaint Management System

Any TOMS user can register a new complaint, or you can use a link provided within your project documentation. Once you register a complaint, the system compares it to the odour impact at the specified location and time.

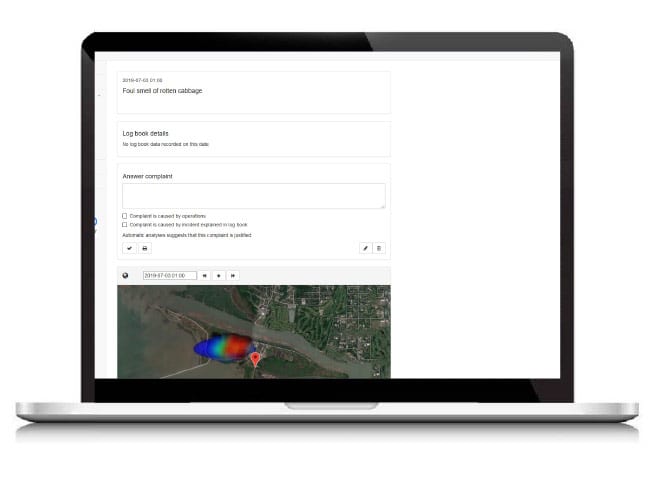

Complaint Justification System

Once you enter a complaint, our TOMS Total Odour Management Software system records the complaint, the time it was made, and any answers supplied by your facility.

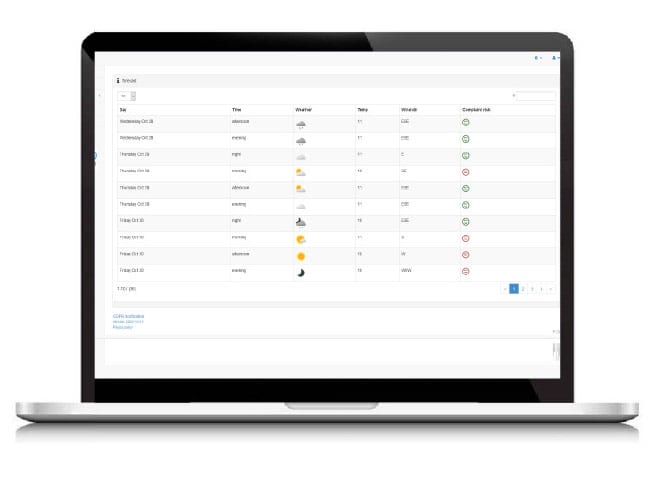

Weather Forecast & Predictive Risk System

TOMS can handle data and information compiled from multiple sources. With a minimal setup procedure, TOMS obtains weather data from a local weather station or the nearest meteorological station.

Advanced Data Analytics

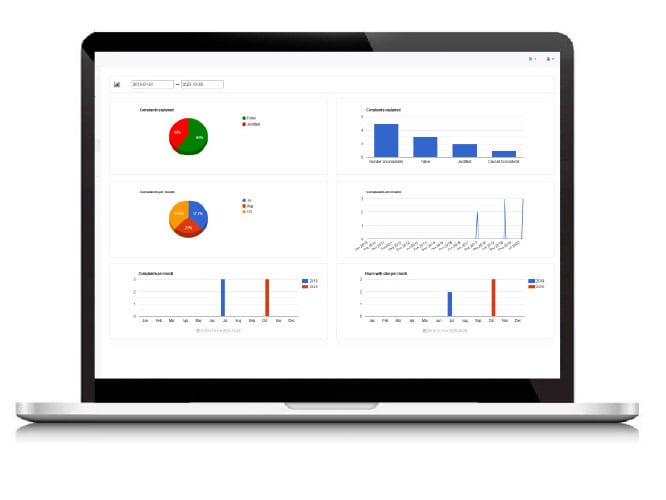

TOMS can dynamically generate a thorough and complete odour report for a user-selected time period. The report details the complaints received each month and indicates whether they are justified.

COMPATIBLE DEVICES

Perfect for SL50

This continuous monitoring station collects data from a variety of sensors and presents it with an easy to understand graphical interface.

AQSafe Friendly

Observes your indoor air quality from a wide variety of sensors, including temperature and humidity. Sensors can track dust, VOC’s, compounds found indoors.

Desktop and Mobile

The robust SIMS2 platform is web based and available on all browsers with internet connectivity. The mobile platform app can be accessed by downloading it from the Google Play Store.

Scentroid is committed to provide our customers with the highest quality products & services. We use established best practices of our industry to meet or exceed your quality expectations. To achieve these objectives and meet the requirements of our customers, we aim to:

- Empower our clients with vast in-depth knowledge, state-of-the-art instruments, and extensive customer support.

- Strive in every aspect of our operation to put our client first and use our research expertise to develop the most innovative and effective products and services in the sensory industry.

- Ensuring the customer needs and expectations are determined and fulfilled with the aim of achieving their utmost satisfaction.

- Striving to deliver products on time with zero defects.

- Training all members of staff in the needs and responsibilities of our quality management system (QMS).

- We strive to continuously improve the effectiveness of the quality management system (QMS) by maintaining, monitoring, reviewing, auditing and enhancing our compliance to ISO 9001:2015

- QMS shall be communicated throughout the organization as well as the system of identifying, reporting, investigating and resolving all non-conformances and taking action to prevent recurrences.

We are so confident of the reliability of our products that we are glad to offer our clients comprehensive 24 month full warranty, covering even the sensors in our equipment! This does not include components such as filters and PID lamps. Our customers get access to our trained and authorized service center for the duration of the warranty subject to the terms and conditions of the warranty. For any related issue, you can reach one of our engineers via email for any technical issue. For fast and efficient support simply email support@scentroid.com