Why Choose SP20 Heated Air Purger

Your One-Stop Sample Bag Cleaning Solution

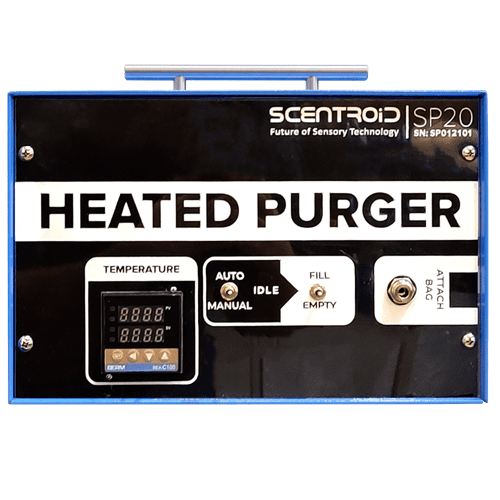

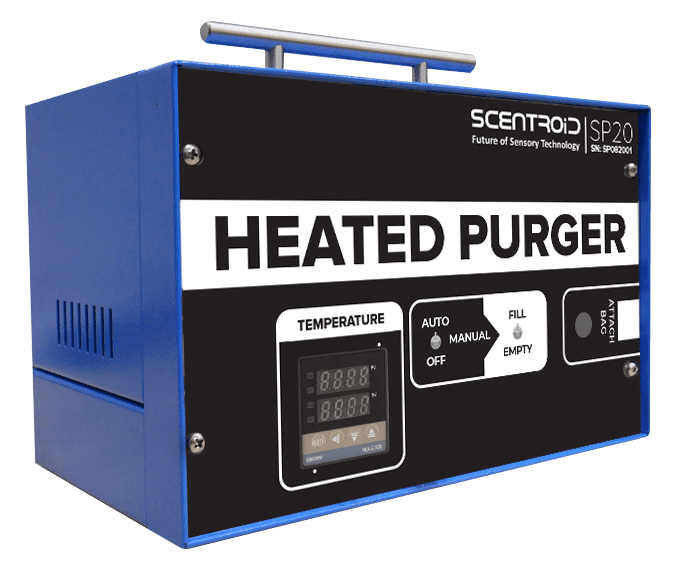

The Scentroid SP20 Heated Air Purger is a revolutionary device designed to provide an effective and reliable cleaning solution for olfactometers, sample bags, PTFE lines, and other equipment that may be contaminated with odours. The SP20 provides hot air at up to 120 degrees Celsius (248 degrees Fahrenheit) to effectively clean stainless steel lines or any of our olfactometers. It can be connected directly to the sample line or to the compressed airline.

Features at a Glance

Rapid Decontamination

The SP20 heated air purger uses both hot air and high vacuum pressure to quickly and effectively decontaminate all sampling equipment

Adjustable Purge Temperature

The SP20 provides heated air at exactly the temperature required. For instance, PTFE sample bags must be purged at 80 °C while stainless steel bags must be purged at 120°C

Fully Automated Operation

SP20 provides complete, automated operation by supplying heated air and then switching to vacuum mode on a predefined cycle frequency

Cycling Hot Air & Vacuuming

The hot air from the unit can also be used to regenerate carbon filters and silica gels in the odour/humidity filter built into the SM100, SC300, or the SS600. The SP20 provides a unique function of cycling between injecting hot air and vacuuming to speed up the purging of Tedlar and other reusable bags.

Benefits of Cyclic Purging

Cyclic Purging significantly reduces the required purging time as the vacuum of the sample bags forcibly pulls odour-causing molecules from the surface of the bag. A typical sample bag purging time of 1 hour using conventional hot air can be reduced to approximately 7 minutes using cyclic purging.

MODE 1

Continuous Hot Air Purging

Used to clean sample lines, PTFE tubes, and to regenerate carbon and silica gel filters

Air temperature is set on the heated air purger by the operator

The unit provides continuous hot air at the specified temperature as monitored by a built-in thermo-couple

MODE 2

Cyclic Purging (Sample Bag Purging)

Used to quickly clean reusable sample bags

The operator sets temperature and pressure as well as the cycle time in seconds (1 – 30)

The unit injects hot air for the duration of the cycle, filling the sample bag

At the end of the injection cycle, the unit switches to vacuum and completely draws the air from the same sample bag

The cycle is continuously repeated creating a lung-like effect

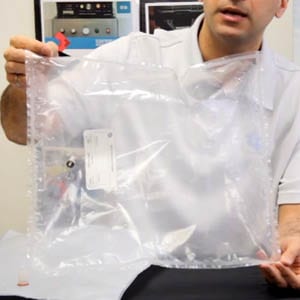

PTFE Sampling Bag

Scentroid is the only manufacturer offering PTFE sampling bags. These bags have a much higher resistance to contamination and Scentroid’s PTFE Sampling Bags have a longer holding time than Tedlar bags. They are also the only accepted bag material for all standards.

Must Utilized Industries:

SP20 Heated Air Purger Specifications

Subject | Specification |

|---|---|

Product Name | Scentroid's Heated Air Purger |

Temperature | Adjustable purge temperature to 120 °C |

Vacuum Power | High Vacuum, up to 0.95 atmospheric pressure |

Cycle Time Setting | 1L to 50L sample bags |

Temperature Monitoring | Continuous |

Ports | Built-in carbon filter on inlet and exhaust ports |

Noise | Quiet operation |

Scentroid Quality Policy

Scentroid is committed to provide our customers with the highest quality products & services. We use established best practices of our industry to meet or exceed your quality expectations. To achieve these objectives and meet the requirements of our customers, we aim to:

- Empower our clients with vast in-depth knowledge, state-of-the-art instruments, and extensive customer support.

- Strive in every aspect of our operation to put our client first and use our research expertise to develop the most innovative and effective products and services in the sensory industry.

- Ensuring the customer needs and expectations are determined and fulfilled with the aim of achieving their utmost satisfaction.

- Striving to deliver products on time with zero defects.

- Training all members of staff in the needs and responsibilities of our quality management system (QMS).

- We strive to continuously improve the effectiveness of the quality management system (QMS) by maintaining, monitoring, reviewing, auditing and enhancing our compliance to ISO 9001:2015

- QMS shall be communicated throughout the organization as well as the system of identifying, reporting, investigating and resolving all non-conformances and taking action to prevent recurrences.

24 Month Warranty

We are so confident of the reliability of our products that we are glad to offer our clients comprehensive 24 month full warranty, covering even the sensors in our equipment! This does not include components such as filters and PID lamps. Our customers get access to our trained and authorized service center for the duration of the warranty subject to the terms and conditions of the warranty. For any related issue, you can reach one of our engineers via email for any technical issue. For fast and efficient support simply email support@scentroid.com