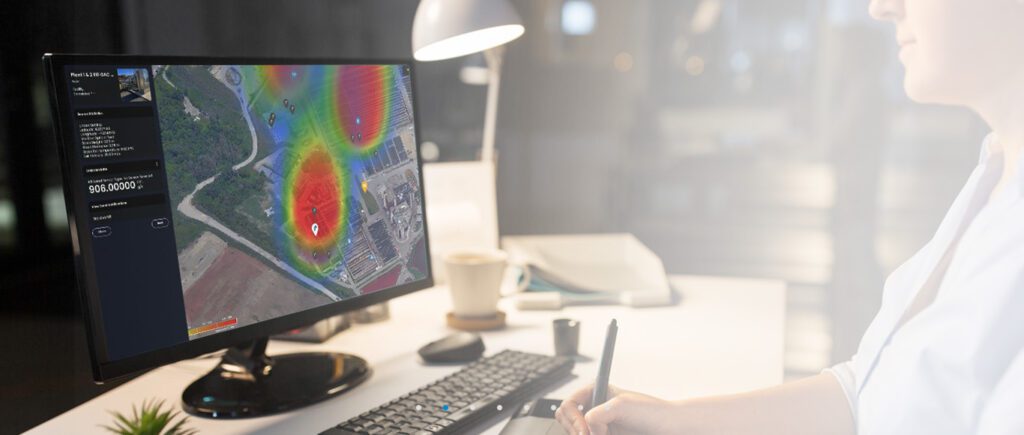

Predicting Odour Complaints Before They Happen: SIMS3’s Powerful Risk Forecasting Tool

Facility managers today face growing pressure to maintain regulatory compliance, minimize environmental impact, and foster strong community relations. One key part of this is staying ahead of potential odour complaints, and predicting odour complaints well before they happen! That’s where Scentroid’s SIMS3 platform steps in. Among its many advanced features, SIMS3 offers complaint risk forecasting, […]

Predicting Odour Complaints Before They Happen: SIMS3’s Powerful Risk Forecasting Tool Read More »