Scentroid's Approach for

Unique and complete air quality monitoring solution catered to your mining operations

Air quality monitoring devices play a critical role in preventing health risks associated with mining operations. These devices allow mining companies to measure the levels of various pollutants in the air, which can help identify potential hazards and implement timely interventions to prevent or reduce harmful impacts. Exposure to high levels of pollutants, such as particulate matter and toxic gases, can cause respiratory diseases, cardiovascular problems, and other health issues, both in workers and nearby communities.

By using air quality monitoring devices, mining companies can detect elevated levels of pollutants and take action to mitigate the risks. Scentroid can assist you with finding the best mining air quality monitoring solution.

This can include implementing pollution control measures, adjusting mining operations to minimize emissions, and providing personal protective equipment to workers.

Stationary Equipment

Establishing a network of monitoring devices allows for the early detection of potentially harmful pollutants and toxic gases. These can result in respiratory illnesses for employees and surrounding communities if left unmonitored. It also provides monitoring data that can be used to assess the health and safety risks associated with mining operations. Finally, early detection of any air quality issues can lead to prompt action and intervention, saving critical resources.

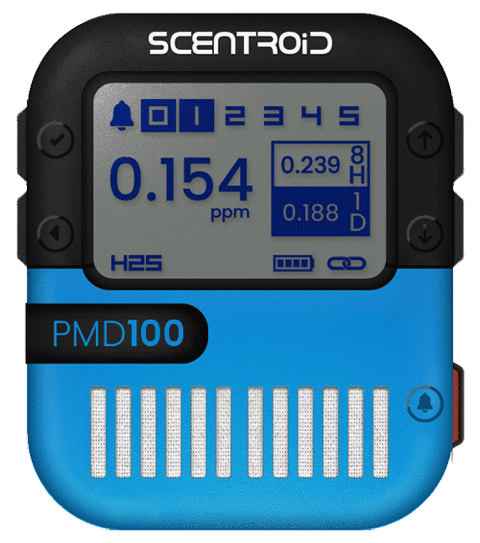

Personal Monitoring

The Scentroid PMD100 air quality monitor has visual and audible alarms to help mining workers protect themselves. By detecting high levels of pollutants, workers can move to safer areas or use protective equipment. The device gives workers real-time data on their personal exposure to pollutants, which is especially important in underground mining. Mine operators can use the device to identify areas with poor air quality and take action. The Scentroid PMD100 promotes safety, improves worker health, and creates a culture of safety.

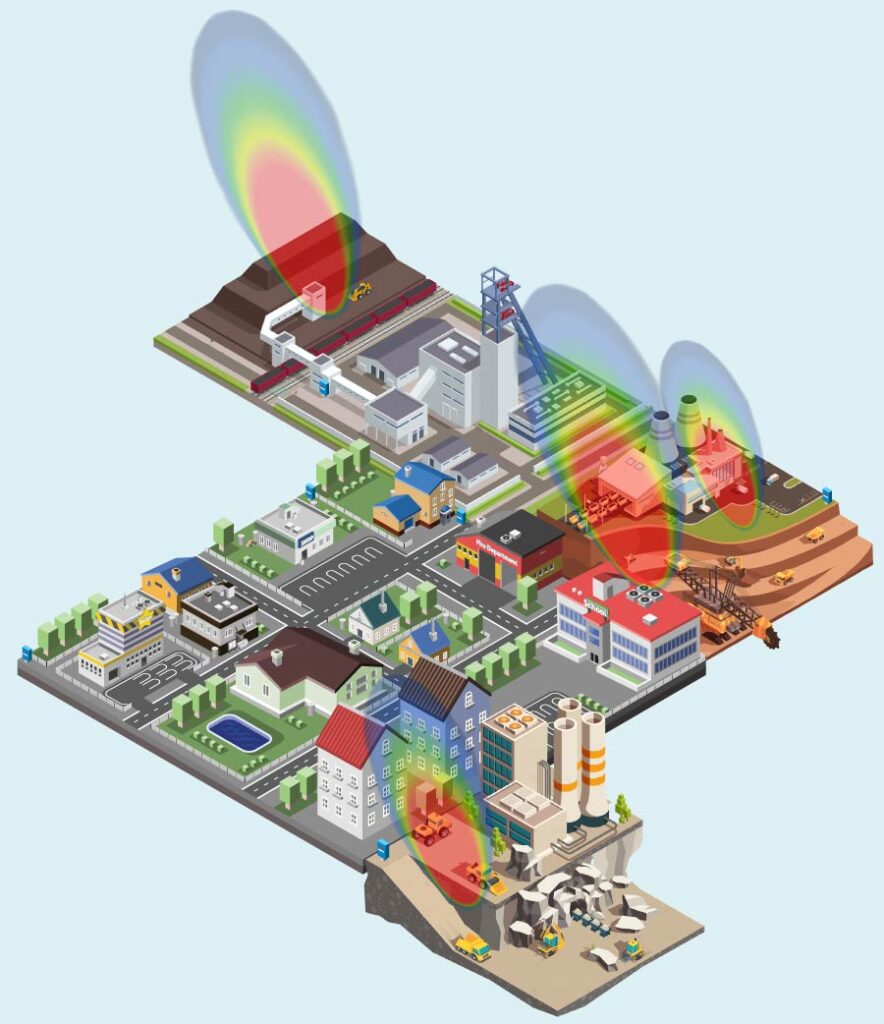

Monitoring Overview

Track your sensitive receptors, and view the direct effects an emission source may have on them, down to the odour unit per second value!

Using “Event Triangulation” SIMS3 can pinpoint the location of unknown sources and determine their contribution to the complaints received

A mining facility may require a network of air quality monitoring devices strategically stationed around the facility perimeter, or throughout the mine itself based on collected data.

Track the impact of upset conditions, maintenance, Firedamp, Black damp, White damp, Stinkdamp, and other facility events using our SIMS3 AI algorithm

Several facility processes may be directly contributing to errant odours. SIMS3 can track the emission rate of all odour sources using amient monitors and reverse dispersion modeling.

Once odour complaints are filed, SIMS3 will collect them and visually present them in a easy to understand, mappable format. SIMS3 will also analyze the contributor of the source that led to the complaint.

In order to ensure the utmost safety of everyone who works within the facility, it is highly recommended that all personnel be provided with a personal monitoring device. Particularly for those who work underground, the implementation of such devices could serve as a crucial defense mechanism, protecting them against unexpected hazards or unsafe conditions. Not only will these devices act as a preemptive measure to minimize the possibility of accidents occurring, but they will also provide a sense of security and reassurance to the workers, allowing them to focus wholeheartedly on their respective tasks without worrying about their well-being. By implementing this practice within our facility, we can actively reinforce our commitment to safety and take proactive measures to ensure that our workforce is protected at all times.

Sensitive Receptor: Local Hotel

Sensitive Receptor: Fire Department

Sensitive Receptor: Local School

Sensitive Receptor: Shopping Center

Unknown Odour Source: Mining Operation

Odour Complaints: Nearby Residential Plaza

Facility Event: Large Scale Excavation

Facility Event: Venting

Monitoring Device: Scentroid SL50 or CTair

Monitoring Device: Scentroid SL50 or CTair

Monitoring Device: Scentroid SL50 or CTair

Monitoring Device: Scentroid SL50 or CTair

Monitoring Device: UrbanScanner US20

Known Odour Source: Coal Storage

Known Odour Source: Diesel Engine Exhaust

Known Pollutant Source: Underground Mining Operations

Pollutants in Mining Operations

Particulate Matter

Mining activities generate airborne dust particles, which can contain various substances depending on the minerals or ores being mined. These particles can include metals, metalloids, and other potentially harmful substances.

Diesel Exhaust Emissions

Diesel-powered equipment used in mining operations can emit hazardous gases and particulate matter, including nitrogen oxides (NOx), sulfur dioxide (SO2), carbon monoxide (CO), and diesel particulate matter (DPM).

Volatile Organic Compounds

Certain mining activities and the presence of specific minerals or ores can release VOCs into the air. These can include chemicals such as benzene, toluene, and xylene, which can have various health effects depending on the specific compound.

Carbon Monoxide

Carbon monoxide (CO) can be generated by the combustion of fuels, such as diesel engines or explosives used in mining. It is a poisonous gas that can cause asphyxiation and is particularly dangerous in confined spaces.

Radon

Radon gas is a natural radioactive gas that can be released from rocks and soils, including those found in mines. Radon inhalation can pose long-term health risks, including an increased risk of lung cancer.

Methane

Methane gas can be present in underground mines, particularly in coal mines. It is highly flammable and poses a significant explosion risk if not properly controlled.

Ask a Scentroid Representative how we can help you with Mining Operation!

How Can Scentroid Help with

Mining Air Quality and Odour Complaints?

Once you activate Scentroid’s devices and enter our software SIMS3, we can use the collected data to determine whether an odour complaint is justified or not. We identify where the great odour sources come from and make justification for you. We also continuously monitoring to help facility maintain better air quality to avoid receiving complaints.

Odour Complaint Justification

Once Scentroid devices are all set and receive all data, SIMS3 will determine whether an odour complaint is justified or not. Red indicates that the complaint was automatically categorized as “justified”, those in green would be recorded, but categorized as “not justified,” those in yellow would be recorded and categorized as “to be justified”. Furthermore, the user can use triangulation to determine the source of unjustified odours.

Triangulation of Unknown Sources

If you are trying to determine the location of potentially unknown sources, SIMS3 offers a triangulation mode and identifier to assist you with pinpointing unknown sources. SIMS3 features the ability to perform triangulation from odour events or from ambient air monitoring equipment readings.

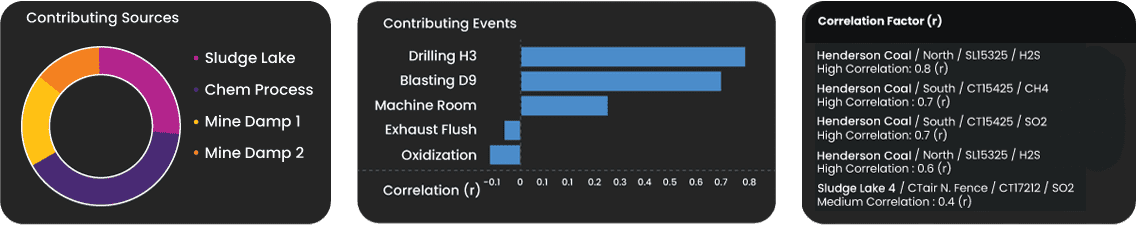

Odour Complaint Analysis

SIMS3 features a correlation module that determines what events caused the greatest odours and what the contributing sources may have been. Furthermore, should your facility’s process events be recorded, SIMS3 will associate those events with odour increases.

Ask a Scentroid Representative how we can help you with Mining Operation!

SIMS3

Sensor Information Management System

SIMS3 sensor information management software, is our all-inclusive software used to view and analyze historical data, run diagnostics, make predictions, and configure various settings for your supported Scentroid device. It offers a complete and integrated suite for ambient air chemical analysis and odor management. SIMS3 can collect data from thousands of devices covering an entire area, using a unique and highly intuitive facility control system.

Powered by

Artificial Intelligence

SIMS3 transforms air quality monitoring and odor complaint management with the power of AI. Our user-friendly interface offers intuitive access to a range of features including pollutant threat assessment, air quality alerts, historical data analysis, sample tracking, plume detection, and complaint management, empowering users of all levels to conduct sophisticated data analytics effortlessly.

Mathematical simulation of how air pollutants disperse in the ambient atmosphere. It is performed with a computer simulation of a pollutant dispersion model

SIMS3 Analytics

View data in several formats including temporal view, statistical view, AQI Analysis view, and heat map.

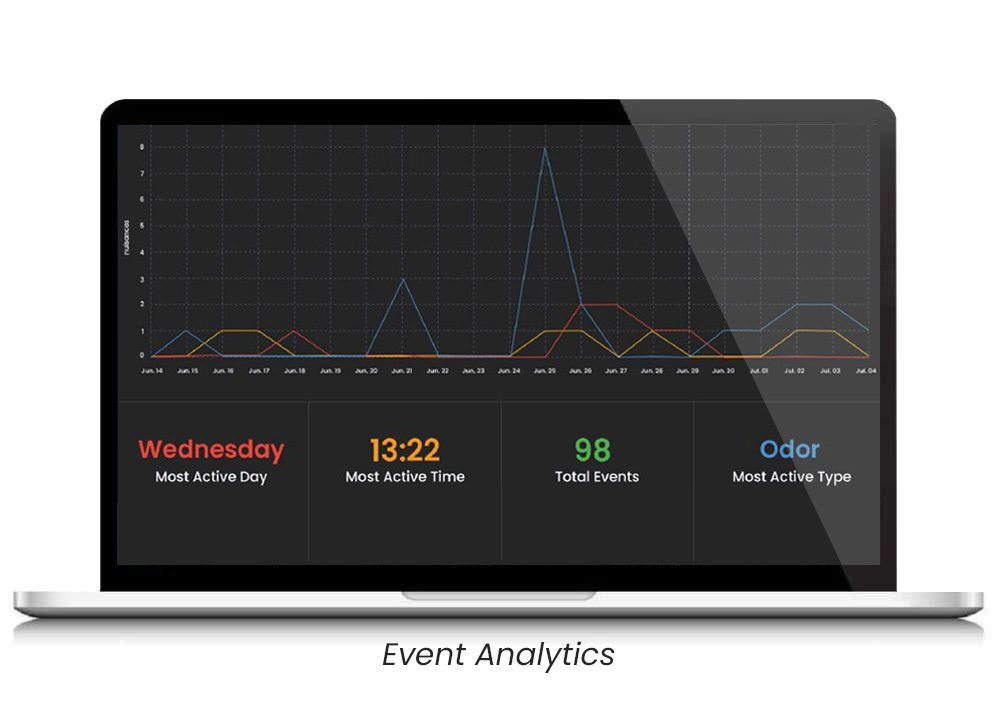

Event Analytics

Take your analytic capabilities even further by analyzing your recorded events, event types, and overall event activity. In this module, you will be able to determine your most triggered event type and the days with the highest recorded activity.

Odor Complaint Analytics

This module allows you to easily determine the justification analytics of all recorded odor events. View which days have had the highest justified or not justified events, view the correlation matrix with contributing events, and see which processes may have a connection to all recorded odor complaints.

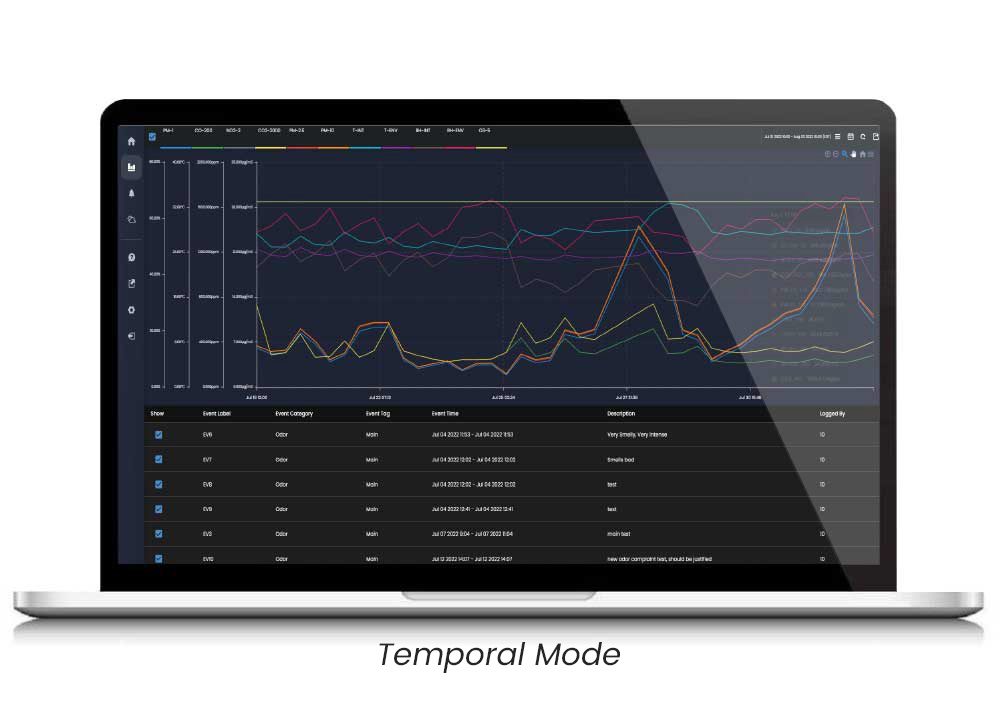

Temporal Mode

As shown here in temporal view, the user can Isolate or compare collected sensor data for any user-defined timeframe in an easy to read chart. Any event or event type that occured within the specified timeframe is also tracked.

Statistical Mode

Isolate and determine individual sensor reading trends with our detailed statistical analysis view. Data is presented as percentages vs concentration for quick reference. A data trend guide displays whether your tracked chemical readings are displaying an increase or decrease.

AQI Analysis

Based on established AQI Thresholds (either automatically generated or user-defined), view recorded AQI for any period of time. This module will also allow you to view how many times AQI exceeded these thresholds, and for how long (percentage).

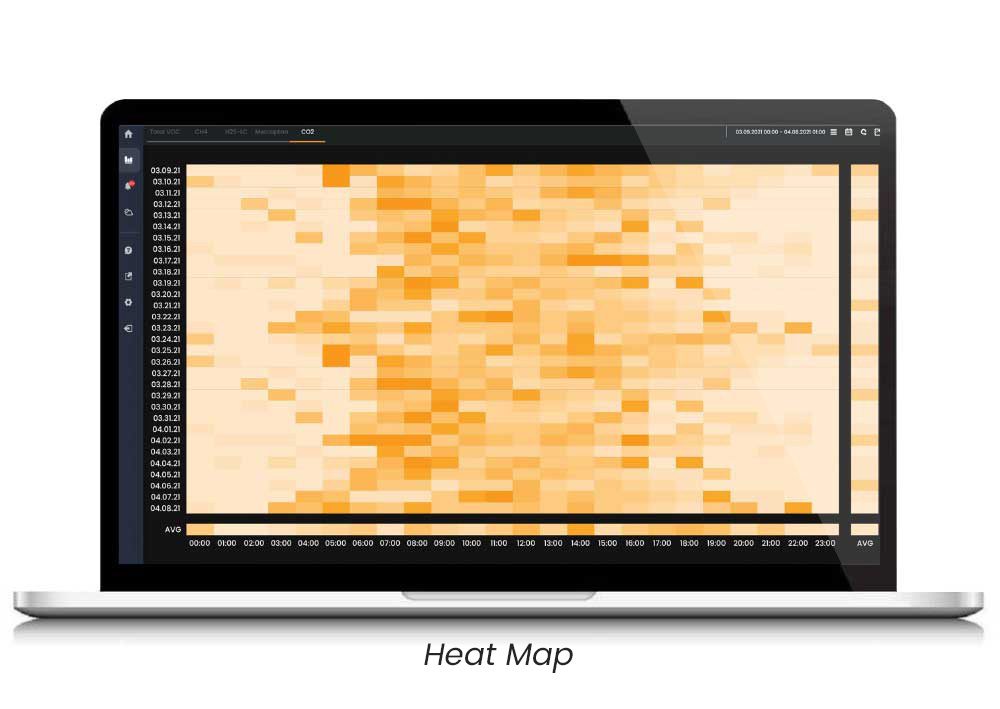

Heat Map

View each individual sensor’s heat map within a user-defined period. Concentration is presented in this format to assist the user with visually defining patterns and trends. Heat map data is presented as date vs. time.

Export Reports

The SIMS3 reporting module provides you with the tools you need to make informed decisions regarding your monitoring projects. At the click of a button, this document generates averages as well as thorough individual sensor reports. Users can schedule weekly, monthly, or annual reports emailed directly to them once generated!

Recommended

Scentroid Services

A comprehensive site overview. Scentroid will formulate a sampling plan and, using a team of qualified engineers and technicians, take analytical and olfactometric measurements and samples at key locations. Scentroid analyzes samples on-site using portable analyzers and olfactometers before being shipped to a comprehensive analytical (ISO 17025) and stationary olfactometric laboratory (EN13725). After analyzing the samples, the data experiences post-processing and is compared against pertinent regulations, guidelines and standards. If exceedance of pollutants is found, Scentroid will recommend suitable approaches in order to fulfill environmental compliance. Optional: atmospheric dispersion modelling can be included in the environmental impact assessment.

In a processing plant, air contamination should be addressed in 2 separate ways: indoors and outdoors. Most common outdoor contaminants come from waste handling, fugitive emissions, and other related activities. While stack sources remain easy to identify, processing plants have many fugitive sources that greatly contribute to the total odour emission of the plant. Scentroid provides a comprehensive source detection and monitoring as part of its odour and indoor/outdoor air pollution management

Determine the severity and extent of the pollutant / odour emissions from your facility. Simulations are processed using the US-EPA designed and approved, AERMOD modelling suite.

Send us your sample bags and our Olfactometric Laboratory will determine their odour concentration in accordance to EN13725:2022, ASTM E679-04, NVN2820, VDI 3881, GB/T14675-93 and/or AS 4323.3.

Other Scentroid Services

Seek advice from our odour monitor experts and environmental consultants to help you improve the accuracy and reliability of your monitoring projects.

Air quality mapping, model verification, and analysis of potentially dangerous sites have all now been made possible. While in flight, built-in chemical sensors can provide remote monitoring.

Ground level readings are used by SIMS3 to conduct back-trajectory to identify unknown sources. Continuous pollution data and field olfactometric data are used along with meteorological data to triangulate the exact location of an odour source.

Scentroid offers a complete and integrated suite for ambient air chemical analysis and odor management, known as SIMS3. Our software utilizes a unique and highly intuitive facility control system, and powerful artificial intelligence to assist you with daily tasks.

We can assist with continuously monitoring the air quality around the boundary of your facility. This is typically used in settings where emissions and pollutants may potentially affect a community.

A team that’s equipped with an SM100i Olfactometer, an OdoTracker personal ambient air monitoring device, a thermal camera, and a noise monitor patrols and collects facility data.

SIMS3 provides the user with the ability to collect, store, determine the correlation factor, and the justification of all complaints that may have been entered against your facility.

Scentroid is capable of providing you and your facility with several reports ranging from SIMS3 outputs, to odour testing results based on your facility’s requirements. Several report types can be autogenerated using our SIMS3 platform.

Ask a Scentroid Representative how we can help you with Mining Operation!

Monitoring Devices

Scentroid provides a wide variety of monitoring devices to assist you with managing air quality concerns for your mining operations. From stationary monitors to handheld olfactometers, Scentroid has you covered!

Mining References

Ghana

Vietnam

Georgia